Where is Artificial Intelligence (AI) already being used in commercial refrigeration and where will it go to next?

.jpg?width=655&height=368&name=MicrosoftTeams-image-(12).jpg)

As with other industries, Artificial Intelligence (AI) technology has been making waves and gaining popularity in the Commercial Refrigeration sector.

In this article we look at where we are seeing AI reshaping the way businesses are managing and monitoring their commercial refrigeration fleets, making it possible to respond faster to changing conditions while remaining cost-effective.

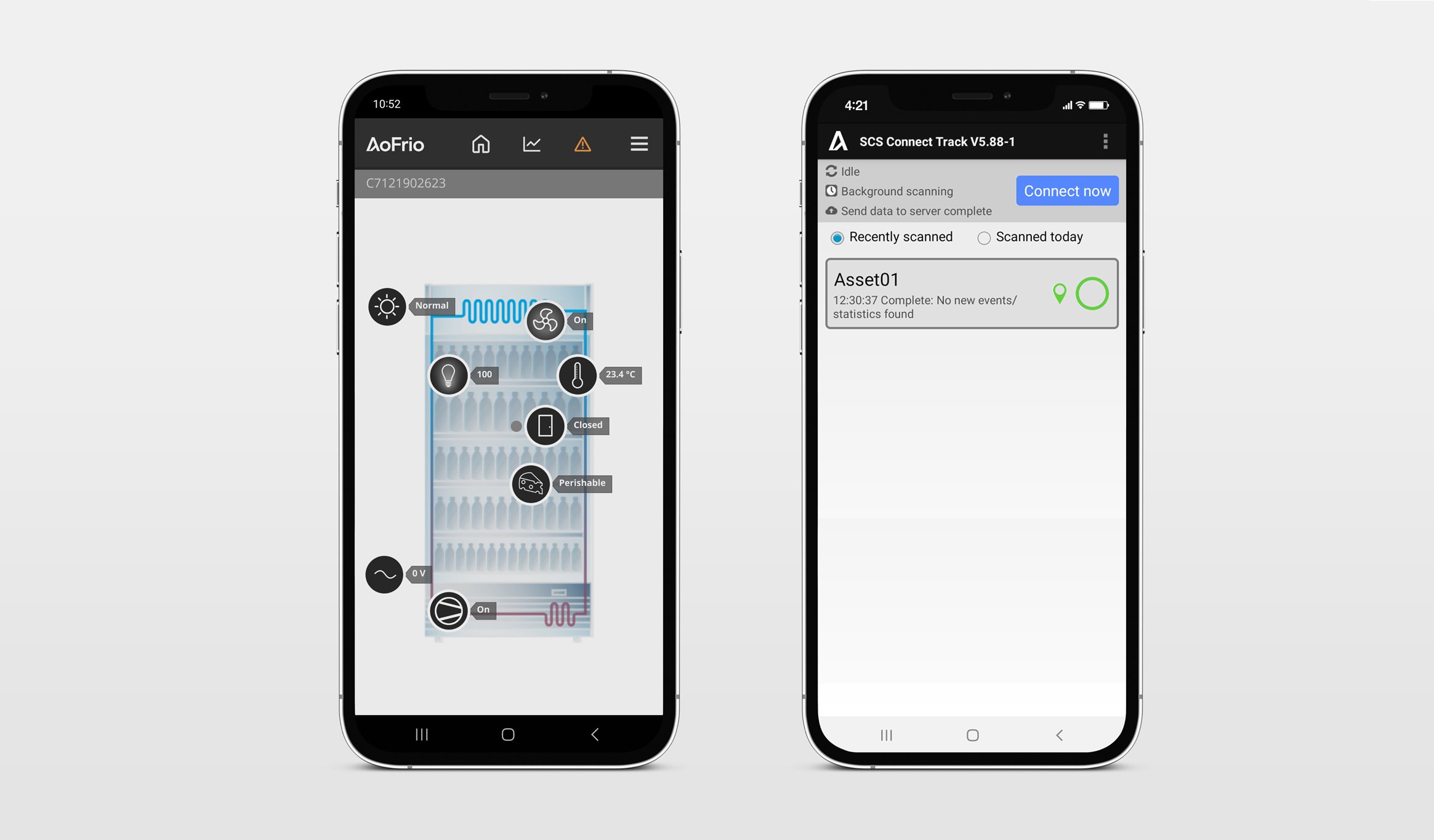

“Predictive or Prognostic Servicing is where we’ve seen the greatest initial impacts from AI in refrigeration fleet management,” says AoFrio’s Customer Success Manager for the Asia Pacific region, St. John Vuetilovoni. “AI technology and computerized maintenance management systems like AoFrio’s IoT ecosystem offer our customers a way to streamline their operations, anticipate where and when to book coolers for servicing, and use large data sets that can drive their power savings and make cooling more sustainable. This has been such a big factor for them in driving down their costs.”

In traditional business models, cleaning, service, and maintenance can cost most companies about 21-40% of their annual operating budget.1 In Commercial Refrigeration, this means manual inspection of refrigeration systems to identify problems which is typically very labour-intensive and time-consuming. Most coolers fail for the following reasons – Aging equipment (34%), Mechanical failure (20%), Operational error (11%), Lack of time for maintenance (9%) and Poor equipment design (8%)2. Technicians visiting coolers in the field need to be aware of all these issues and arrive ready with replacement parts, often visiting sites out of hours to reduce downtime for coolers and interruption to business operations, especially those with direct consumer relationships like restaurants and supermarkets.

AI-based cooler systems are also starting to make more use of preventative functions that require no human interaction. For example, a cooler with installed AI-sensor technology can identify common issues and faults before they incapacitate the cooler. Over time, this predictive maintenance will make servicing easier to plan and more focused.

“Another AI benefit we are seeing develop is an ever-increasing number of businesses who are optimizing the energy consumption of their commercial fleets,” says AoFrio’s Manager of Executive Operations and Sustainability, Danielle Scott. “By close analysis of energy usage patterns across their fleet, customers can use our smart SCS controllers and preset parameters to reduce equipment runtime during non-peak hours. This approach allows refrigeration systems to consume energy efficiently, saving businesses a considerable amount on their energy bills.”

“In just one scenario I am aware of, a refrigeration system equipped with thermal imaging sensors can detect fluctuations in external room temperature, and then use it’s AI-smarts to adjust compressor load and ambient humidity to ensure the cooler is operating at optimal efficiency. This saves on energy consumption, all without human invention.”

Where to next for AI in Commercial Refrigeration?

First used as a concept in the 1990s3, Big Data has been largely driven by improvements in AI. AI-powered systems can sift through the vast amounts of data that coolers can gather and send through to the Cloud for further analysis and insights. This level of analysis was simply too time-consuming with human teams, limited data storage, and manual systems. Smart analytics engines can provide a significant mass of real-time data based on refrigeration performance, available inventory, identifying patterns as well as predicting consumer behavior and impacts. “By utilizing this comprehensive data in real-time rather than at month- or week-end, businesses can respond to local changes more quickly,” says Mr Vuetilovoni.

“AI also already has the ability to integrate with business systems, such as financial or supply chain management software,” he continues. “This gives asset owners holistic solutions that can optimize their operations and reduce wasted time. In future, AI will continue to help them improve their decision-making based on timely data and fact-based recommendations provided through predictive features that forecast and anticipate opportunities.”

The future of commercial refrigeration certainly includes AI. It already knows so much about Commerical Refrigeration and has the potential to do even more once integrated with new and retrofitted coolers. With the benefits of predictive maintenance, optimized energy consumption, enhanced analytics capabilities, and easier integration with other business systems, we predict that businesses using commercial refrigeration will only continue to embrace and expand this smart technology. AI knows how, so we can do.

1. CMM. (2020, April). “What percentage of your operating budget is spent on cleaning/maintenance equipment and supplies?”

2. Parker, K. (2020, March). “An evolutionary challenge faces the maintenance function.” from Plant Engineering.

3. ATScale (2023, September). Company knowledgebase article - “What is Big Data?”